Latest Updates

-

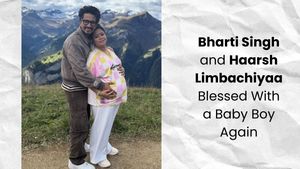

Bharti Singh-Haarsh Limbachiyaa Welcome Second Child, Gender: Couple Welcome Their Second Baby, Duo Overjoyed - Report | Bharti Singh Gives Birth To Second Baby Boy | Gender Of Bharti Singh Haarsh Limbachiyaa Second Baby

Bharti Singh-Haarsh Limbachiyaa Welcome Second Child, Gender: Couple Welcome Their Second Baby, Duo Overjoyed - Report | Bharti Singh Gives Birth To Second Baby Boy | Gender Of Bharti Singh Haarsh Limbachiyaa Second Baby -

Bharti Singh Welcomes Second Son: Joyous News for the Comedian and Her Family

Bharti Singh Welcomes Second Son: Joyous News for the Comedian and Her Family -

Gold & Silver Rates Today in India: 22K, 24K, 18K & MCX Prices Fall After Continuous Rally; Check Latest Gold Rates in Chennai, Mumbai, Bangalore, Hyderabad, Ahmedabad & Other Cities on 19 December

Gold & Silver Rates Today in India: 22K, 24K, 18K & MCX Prices Fall After Continuous Rally; Check Latest Gold Rates in Chennai, Mumbai, Bangalore, Hyderabad, Ahmedabad & Other Cities on 19 December -

Nick Jonas Dancing to Dhurandhar’s “Shararat” Song Goes Viral

Nick Jonas Dancing to Dhurandhar’s “Shararat” Song Goes Viral -

From Consciousness To Cosmos: Understanding Reality Through The Vedic Lens

From Consciousness To Cosmos: Understanding Reality Through The Vedic Lens -

The Sunscreen Confusion: Expert Explains How to Choose What Actually Works in Indian Weather

The Sunscreen Confusion: Expert Explains How to Choose What Actually Works in Indian Weather -

On Goa Liberation Day 2025, A Look At How Freedom Shaped Goa Into A Celebrity-Favourite Retreat

On Goa Liberation Day 2025, A Look At How Freedom Shaped Goa Into A Celebrity-Favourite Retreat -

Daily Horoscope, Dec 19, 2025: Libra to Pisces; Astrological Prediction for all Zodiac Signs

Daily Horoscope, Dec 19, 2025: Libra to Pisces; Astrological Prediction for all Zodiac Signs -

Paush Amavasya 2025: Do These Most Powerful Rituals For Closure On The Final Amavasya Of The Year

Paush Amavasya 2025: Do These Most Powerful Rituals For Closure On The Final Amavasya Of The Year -

As The Last New Moon Of 2025 Approaches, Make A Wish Based On Your Rising Sign

As The Last New Moon Of 2025 Approaches, Make A Wish Based On Your Rising Sign

Safety Isn’t Optional: What Pharma Factories Must Learn From The Telangana Tragedy

This June 30 wasn't an ordinary Monday morning. A powerful explosion ripped through a pharmaceutical unit on the outskirts of Hyderabad, turning a regular workday into a nightmare. At least 37 workers lost their lives, many others were injured, and a community was left stunned and grieving.

The blast took place at Sigachi Industries Pvt. Ltd., a plant involved in producing microcrystalline cellulose-a powder used in medicines, food, and cosmetics around the world. While the exact cause is still being investigated, early reports suggest a major failure within a key processing unit.

But this isn't just about one factory, one fire, or one region. This is about what happens when safety becomes an afterthought in high-risk environments.

Behind The Machines: The Human Factor

In factories like these, workers don't deal with just paperwork and keyboards. They work near pressurised systems, heat, chemicals, and sometimes, invisible risks like airborne dust. Most of the time, everything works smoothly. Until something small goes wrong and triggers something much bigger.

That's what makes safety so crucial. It's not just about avoiding fines or ticking boxes. It's about ensuring that the people who clock in each day go home safe.

No one walks into work thinking it might be their last day. But for factory workers handling sensitive chemicals or powders, safety systems are the thin line between routine and disaster. Here are key takeaways every factory, and every industry leader, needs to take seriously:

What Every Factory Should Pay Attention To

Even before a final report tells us what happened at Sigachi, there are already clear lessons that pharma and chemical units across the country need to take seriously.

1. Pressure Needs an Exit

When

a

system

builds

up

pressure

whether

it's

a

dryer,

a

reactor,

or

a

steam

line

there

needs

to

be

a

way

for

it

to

escape

safely.

If

not,

the

result

is

often

explosive.

That

means;

Relief

valves,

Automatic

shutoffs,

Real-time

pressure

monitoring,

none

of

these

are

extras.

They're

basics.

2. Dust Can Be Dangerous

It sounds harmless, but many pharmaceutical powders are highly combustible. If they collect in closed spaces or float in the air unchecked, they can ignite with a spark.

Factories need:

- Ventilation systems

- Regular deep cleaning

- Proper dust collection units

3. Design Matters

Buildings that house high-risk equipment must be designed for worst-case scenarios. That includes:

- Blast-proof partitions

- Isolated high-risk areas

- Clearly marked, unobstructed evacuation paths

The idea is simple: if something does go wrong, the damage shouldn't spread.

4. Training Isn't A One-Time Thing

Everyone from floor workers to shift supervisors should know:

- How to shut down machinery in an emergency

- How to evacuate safely

- How to use safety gear confidently

- Safety drills, refresher sessions, and hands-on demos need to be part of routine life.

5. Maintenance Can't Wait

Safety devices are only as good as their last inspection. That means:

- Checking that alarms actually work

- Cleaning filters, valves, and ducts regularly

- Replacing worn parts before they become dangerous

- If you wait until something breaks, you've waited too long.

Safety Is a Culture, Not a Checklist

The Telangana tragedy shows us how much is at stake not just for one company, but for the industry as a whole. When safety becomes a formality, everyone loses. But when it's built into the daily rhythm of a workplace-respected, practised, and prioritised, it saves lives.

The reality is most accidents are preventable. And every life saved is worth the effort.

Factories aren't faceless. They're made up of people-operators, engineers, cleaners, technicians, each one trusting that the systems around them are designed to protect them.

The blast at Sigachi Industries reminds us what happens when that trust is broken.

It's time every workplace, especially those handling heat, chemicals, or combustible materials, takes a long, hard look at its safety practices not after a tragedy, but before.

Because safety doesn't slow things down. It keeps everything moving forward-including people's lives.

Click it and Unblock the Notifications

Click it and Unblock the Notifications